The Core of Modern Electric Vehicles

At the heart of any efficient electric vehicle lies its powertrain, and the electric vehicle transaxle is a marvel of modern engineering within this system. It masterfully integrates the electric motor, transmission gears, and differential into a single, compact, and highly efficient unit. This intelligent consolidation is not merely about saving space or weight; it is about optimizing the flow of power from the battery to the wheels. By minimizing energy loss and ensuring seamless torque delivery, a high-quality transaxle provides the smooth, quiet, and instantly responsive driving experience that has become the hallmark of electric mobility. From lightweight personal mobility scooters to robust commercial utility vehicles, the design and construction of the transaxle directly influence handling, power output, and the overall longevity of the vehicle. It is the unseen powerhouse that diligently translates stored electrical energy into controlled, reliable motion, making it a critical component for any application.

A Glimpse into a Premier Transaxle Production Facility

Stepping into a state-of-the-art transaxle production facility, such as RUIPU MACHINERY’s expansive 6,000 square meter plant, reveals a world defined by precision, innovation, and meticulous control. This is where raw, high-grade materials are systematically transformed into sophisticated drive systems through a synergistic combination of advanced automated processes and the irreplaceable oversight of skilled technicians and engineers. The factory floor is a symphony of cutting-edge machinery, from high-precision CNC gear hobbing machines to comprehensive testing apparatuses that validate every aspect of performance. Every single stage of the production cycle is governed by a rigorous quality policy rooted in the principles of prevention, control, and continuous improvement. This dynamic environment, fostered by a corporate spirit of honesty, pragmatism, and innovation, ensures that every transaxle and component that leaves the facility not only meets but often exceeds the highest international standards for quality and reliability.

Mastering Electric Transaxle Manufacturing

The intricate process of electric transaxle manufacturing is a delicate and demanding balance of robust mechanical engineering and sophisticated electronic design. At RUIPU MACHINERY, this complex process is elevated by a significant competitive advantage: the complete, in-house design and independent production of all core components. This vertical integration strategy grants the company unparalleled control over quality, from the initial material selection to the final assembly and testing. It allows for rapid innovation and the ability to fine-tune every element for optimal performance. This capability is powered by a dedicated team of over five senior engineers and strengthened by ongoing collaborations with leading universities. This deep focus on research and development fuels constant product diversification, enabling RUIPU to adeptly meet the ever-changing demands of the global market and create custom-tailored solutions that are both powerful and exceptionally dependable.

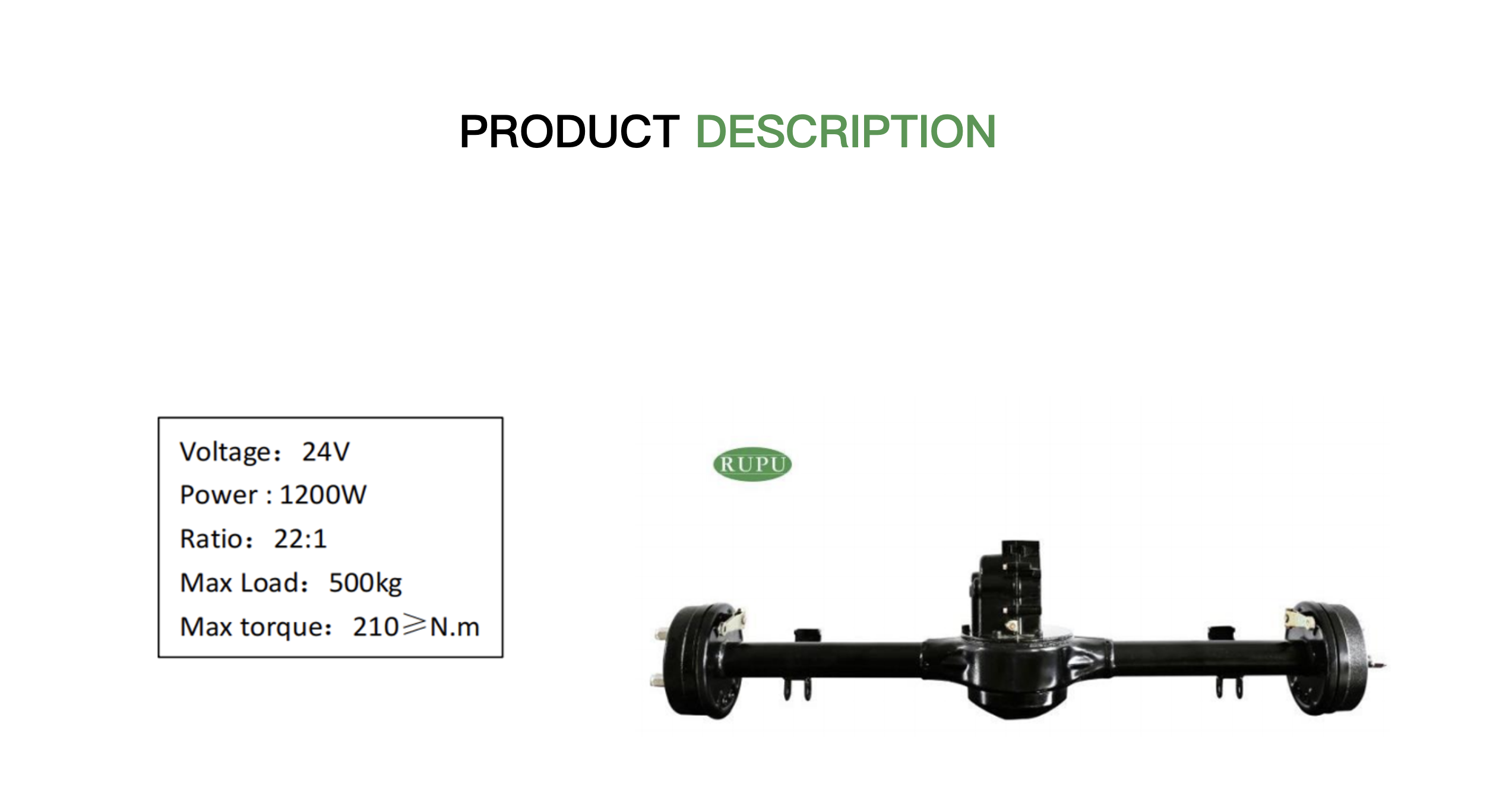

Engineering Excellence: The RUPU Electric Rear Axle

The true measure of a factory's capability is reflected in the quality and performance of the products it creates, and the RUPU Electric Rear Axle serves as a powerful testament to engineering excellence. This specific motorized axle is meticulously engineered for superior performance, operating at a robust 24V and delivering a formidable 1200W of power. Its precisely crafted 22:1 gear ratio is strategically designed to maximize torque output, generating a peak torque that exceeds 210 N.m. This impressive specification ensures wonderfully smooth acceleration and highly responsive handling, even when subjected to substantial loads of up to 500kg. Whether it is integrated into last-mile delivery vehicles, advanced agricultural equipment, or personal mobility aids, this axle provides the exceptional durability and efficiency that RUIPU's clients worldwide have come to expect. It embodies the company's promise of enhanced functionality, increased vehicle lifespan, and uncompromising performance.

A Global Partner with a Customer-First Approach

RUIPU MACHINERY’s unwavering commitment to engineering excellence has successfully propelled its products onto the global stage, with exports reaching more than 30 countries across key markets in Europe, North America, Australia, and Southeast Asia. This impressive international success is built upon a foundational corporate philosophy of taking complete responsibility for every customer, ensuring their ultimate satisfaction, and creating tangible, lasting value. A key aspect of this customer-centric approach is the company's remarkable ability to develop and deliver customized products with special structures tailored to unique client requirements. This flexibility demonstrates a profound understanding of diverse market needs and a genuine willingness to partner collaboratively with clients to solve their most difficult engineering challenges. This commitment ensures fast development cycles, reliable performance, and attentive service that builds long-term trust and mutual growth.

The Future is Driven by Innovation

The global journey towards a fully electric future is being paved with innovation, precision, and a dedication to quality. A leading Electric transaxle factory is much more than just a manufacturer of parts; it is a crucial enabler of progress, providing the critical drive components that make clean, efficient, and powerful transportation a reality for millions. RUIPU MACHINERY perfectly exemplifies this vital role, leveraging its deep expertise in gear manufacturing, its uncompromising commitment to quality, and its customer-first philosophy to consistently drive the industry forward. As they continue to innovate and expand their global reach, they warmly welcome new and existing partners to join them in building a more mobile, efficient, and sustainable world, one high-performance electric transaxle at a time.