The Core of Modern Electric Vehicles: The Transaxle

The electric vehicle transaxle is a masterpiece of integration and efficiency. Unlike traditional combustion engine vehicles that require separate components for the engine, transmission, and differential, an electric transaxle combines an electric motor, a gearbox, and the differential into one compact and cohesive unit. This integrated design offers numerous advantages, including reduced weight, fewer moving parts, lower energy loss, and a more streamlined manufacturing process. It is the central nervous system of the drivetrain, responsible for translating electrical energy from the battery into mechanical force that turns the wheels. The precision engineering required to produce a durable and high-performing electric vehicle transaxle cannot be overstated, as its performance directly impacts the vehicle's range, acceleration, and operational quietness.

A Look Inside a State-of-the-Art Transaxle Production Facility

A modern transaxle production facility is a far cry from a traditional assembly line. It is a highly controlled environment where technology and human expertise converge. Imagine a sprawling 6,000 square meter factory, like the one operated by RUIPU MACHINERY in Jinhua, Zhejiang. This space is meticulously organized to facilitate a seamless workflow, from raw material intake to final product testing. Advanced CNC machines carve gears with micron-level accuracy, while automated systems handle assembly to ensure consistency. A key area within any leading transaxle production facility is dedicated to quality assurance. Here, advanced testing equipment simulates real-world conditions, subjecting each transaxle to rigorous stress tests to verify its load capacity, torque output, and long-term durability. This commitment to quality control is fundamental to building a reputation for reliability in the competitive global market.

RUIPU MACHINERY: Pioneering Electric Transaxle Manufacturing

RUIPU MACHINERY exemplifies the pinnacle of modern electric transaxle manufacturing. With a deep-seated commitment to international development and technological advancement, the company has established itself as a premier global supplier. What sets RUIPU apart is its philosophy of in-house expertise. All core components are independently designed and produced, giving the company complete control over the quality and performance of the final product. This is powered by a dedicated team of over five senior engineers and strategic collaborations with universities to foster innovation and product diversification. The success of this approach is evident in their global reach, with products exported to over 30 countries across Europe, North America, and Asia. This isn't just manufacturing; it's a holistic process of research, development, and precision engineering that anticipates and meets the evolving demands of the market.

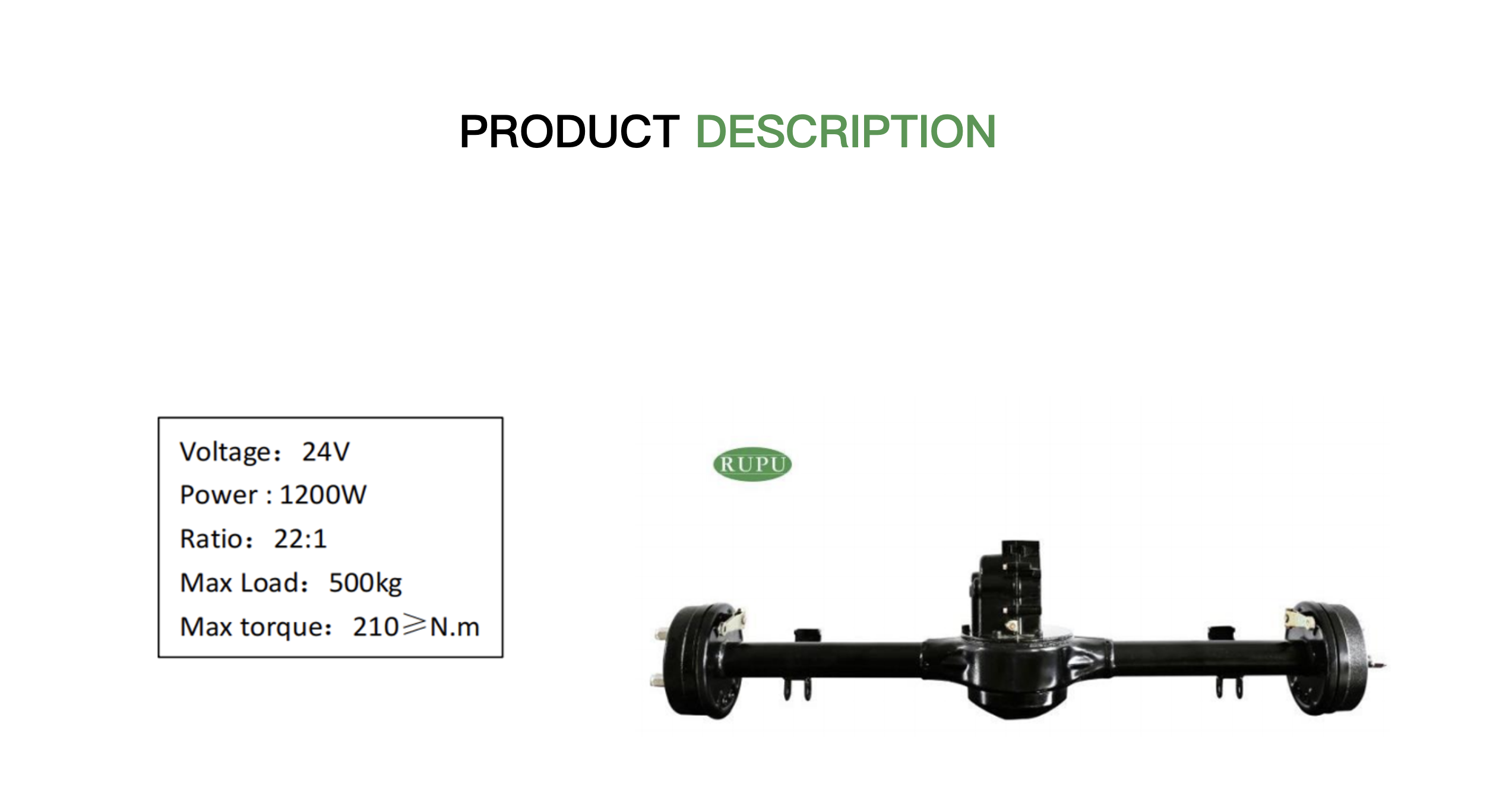

Engineering Excellence: A Showcase of RUPU's Product Capabilities

The tangible result of RUIPU's advanced manufacturing process is a product line that stands for power and reliability. A prime example is their flagship electric axle solution. Operating at an efficient 24V, it delivers a formidable 1200W of power. Its meticulously engineered 22:1 gear ratio provides an optimal balance between torque and speed, ensuring smooth and responsive power delivery. This axle is built to endure, supporting a maximum load of 500kg and generating an impressive maximum torque exceeding 210 N.m. These specifications are not just numbers on a page; they translate into real-world capability, enabling vehicles to handle heavy loads and navigate challenging terrains with ease. This level of performance, born from a world-class Electric transaxle factory, makes it an ideal choice for a wide range of applications, from commercial utility vehicles to sophisticated personal mobility devices.

Driven by a Culture of Quality and Customer Satisfaction

Technology and infrastructure are only part of the equation. The enduring success of RUIPU MACHINERY is also built on a strong corporate culture defined by its spirit of Honesty, Civilization, Pragmatism, and Innovation. This ethos permeates every level of the organization, from the factory floor to the executive office. The company's quality policy—Prevention, Control, Improvement, Enhancement, Leadership, Progress, Service, Integrity—is a guiding principle that ensures a proactive approach to excellence. This customer-centric philosophy means that RUIPU is not just a manufacturer but a partner, dedicated to creating value and ensuring satisfaction. Their ability to develop customized products with special structures demonstrates a flexibility and attentiveness that sets them apart, fostering long-term relationships built on trust and mutual growth.

Choosing the Right Partner for Future Growth

In the rapidly expanding world of electric vehicles, selecting the right supplier is a decision of paramount importance. The choice of an Electric transaxle factory impacts everything from product performance to supply chain reliability. Companies like RUIPU MACHINERY, with their vertically integrated production, commitment to research and development, and a culture rooted in quality and customer service, represent the ideal partner for businesses looking to innovate and lead. Their proven track record and state-of-the-art facility provide the assurance needed to build the next generation of electric-powered solutions with confidence. By partnering with a leader in electric transaxle manufacturing, companies can ensure they are well-equipped for a successful and sustainable future.