The Core of Modern Mobility: Inside a Premier Electric Transaxle Factory

As the world accelerates towards a sustainable future, the electric vehicle (EV) industry has become a cornerstone of technological innovation. At the heart of this revolution are the intricate components that drive these vehicles forward. A leading electric transaxle factory, such as RUIPU MACHINERY, plays a pivotal role in this transformation by engineering the very systems that define an EV's performance, efficiency, and reliability. These facilities are not just manufacturing plants; they are hubs of innovation where advanced engineering meets precision production to power the next generation of transportation.

Understanding the Electric Vehicle Transaxle

The electric vehicle transaxle is a marvel of modern engineering, representing a significant evolution from the traditional drivetrains found in internal combustion engine vehicles. It is a compact, integrated unit that typically combines the electric motor, a single-speed or multi-speed gearbox, and the differential into one cohesive system. This integration is key to its effectiveness. By housing these critical components together, the transaxle reduces weight, saves precious space, and minimizes energy loss, which directly translates to increased range and better vehicle dynamics. For any EV, the quality and design of its transaxle are fundamental to delivering a smooth, quiet, and powerful driving experience, making the selection of a manufacturing partner incredibly important.

A Glimpse into a State-of-the-Art Transaxle Production Facility

Step inside a modern transaxle production facility, and you will witness a symphony of advanced technology and meticulous processes. At RUIPU MACHINERY's expansive 6,000 square meter plant in Jinhua, Zhejiang, the commitment to quality is evident at every stage. The process begins with superior raw materials and moves through precision machining, gear cutting, and assembly in a controlled environment. Advanced testing equipment is utilized to scrutinize every component and final assembly, ensuring they meet strict performance and durability standards. This rigorous approach to quality control, guided by a policy of prevention, control, and continuous improvement, is what distinguishes a leading facility. It’s a place where every gear, bearing, and housing is crafted with the utmost precision, as the performance of the final electric vehicle transaxle depends on the perfection of its parts.

The RUIPU Method of Electric Transaxle Manufacturing

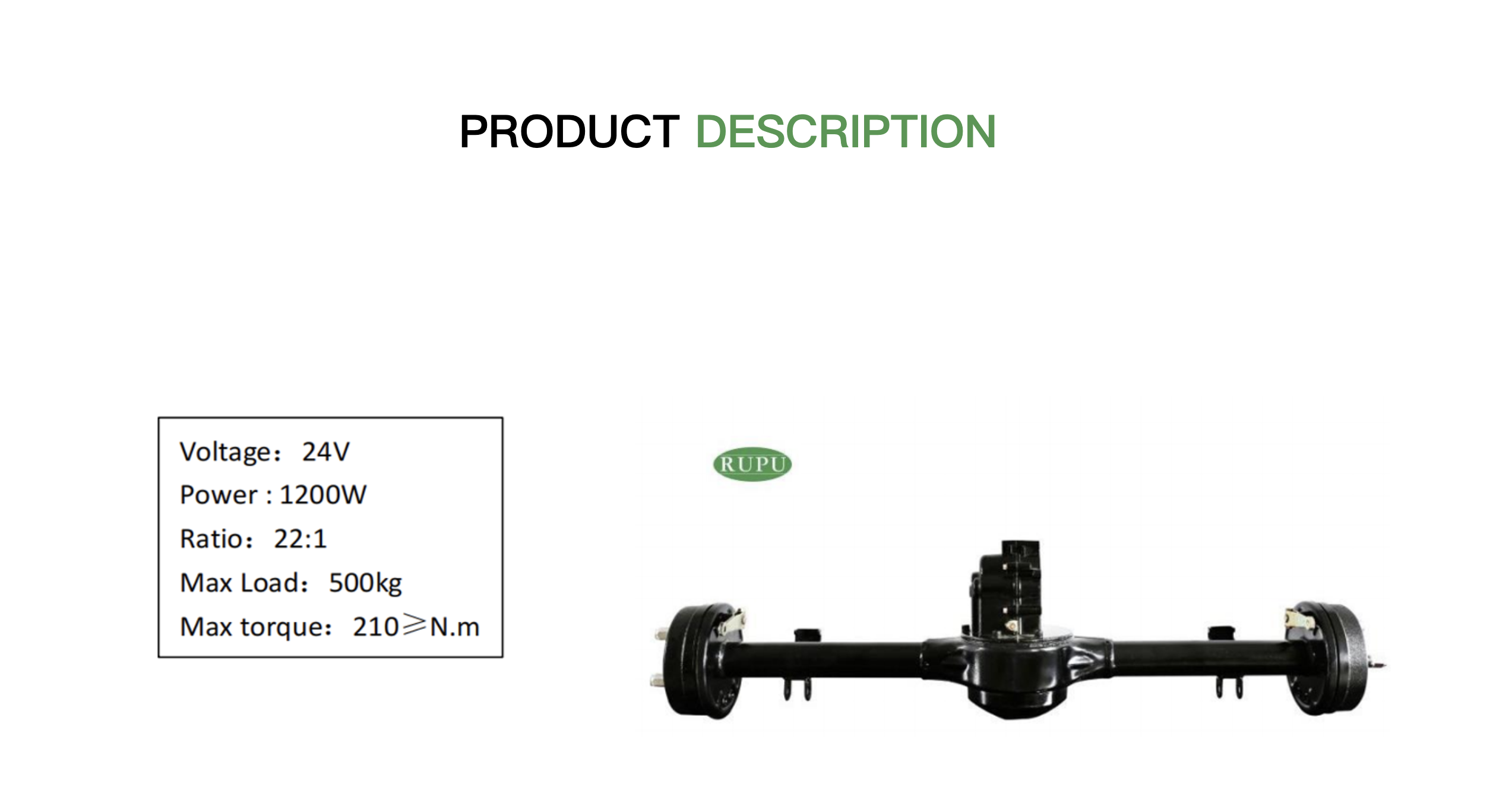

RUIPU MACHINERY has cultivated a specialized approach to electric transaxle manufacturing that combines in-house expertise with a culture of innovation. With a dedicated team of over five senior engineers and strategic collaborations with universities, the company remains at the forefront of product development. A core tenet of our philosophy is the independent design and production of all essential components. This autonomy allows for unparalleled quality control and the flexibility to innovate rapidly. A prime example of this engineering excellence is the high-performance RUPU rear axle system. Designed for extraordinary efficiency, this product operates at 24V with a robust 1200W output. It features a precise 22:1 gear ratio and can handle a maximum load of 500kg. With an impressive maximum torque of 210 N.m, it delivers superior control and power for a wide range of applications, showcasing the tangible results of our sophisticated manufacturing process.

Global Expertise and Customized Solutions

An electric transaxle factory must be more than just a producer; it must be a global partner capable of meeting diverse market demands. RUIPU MACHINERY has established a strong international footprint, exporting products to over 30 countries across Europe, North America, Australia, and Southeast Asia. This global reach is built on a foundation of trust, reliability, and the ability to deliver solutions that work. Recognizing that no two applications are exactly alike, we specialize in offering customized products with special structures. Our agile development process ensures that we can quickly create reliable, high-performance solutions tailored to specific client needs. This customer-centric approach, rooted in our philosophy of creating value and ensuring satisfaction, makes us a preferred partner for companies worldwide seeking cutting-edge electric drive technology.

Driving the Future with Integrity and Innovation

Ultimately, the success and progress of the electric vehicle industry depend on the quality and ingenuity of its core components. A world-class transaxle production facility is the engine room of this progress, providing the critical systems that make clean, efficient transportation a reality. At RUIPU MACHINERY, our corporate spirit of honesty, civilization, pragmatism, and innovation guides every decision we make and every product we create. By combining advanced technology, rigorous quality control, and a deep commitment to our customers, we are not just manufacturing parts; we are helping to build a more sustainable and efficient future. We continue to welcome new and existing partners to join us on this journey of mutual growth and technological advancement.