Understanding the Electric Vehicle Transaxle

At its core, an electric vehicle transaxle is a marvel of integration. Unlike traditional combustion engine vehicles that have separate transmissions, axles, and differentials, an electric transaxle combines these functions into a single, compact unit alongside the electric motor. This integrated design is a game-changer for several reasons. It significantly reduces the overall weight and size of the drivetrain, freeing up valuable space for battery packs or increased cabin room. This consolidation also minimizes energy loss between components, leading to higher overall efficiency and extended vehicle range. The result is a quieter, smoother, and more responsive driving experience, which has become a hallmark of high-quality electric vehicles. This component is not merely a part of the powertrain; it is the heart that delivers controlled power to the wheels, defining the vehicle's character and capability.

The Complex World of Electric Transaxle Manufacturing

The process of electric transaxle manufacturing is a highly sophisticated endeavor that demands meticulous attention to detail and advanced technological capabilities. It begins with the selection of high-grade materials, such as robust alloys capable of withstanding immense torque and stress over long periods. The manufacturing process itself relies on precision engineering, where gears are cut with microscopic accuracy to ensure seamless meshing and minimal operational noise. Tolerances are incredibly tight, as even the slightest deviation can impact performance and longevity. At RUIPU MACHINERY, we take this a step further by designing and producing all core components in-house. This vertical integration allows for unparalleled quality control, from the initial raw material to the final assembled product. Our commitment to this rigorous process ensures that every transaxle we produce meets the highest standards of reliability and performance.

A Look Inside a Leading Transaxle Production Facility

A modern transaxle production facility is a dynamic environment where automation and human expertise converge. Within our expansive 6,000 square meter factory in Jinhua, Zhejiang, you will find state-of-the-art CNC machinery working in harmony with our skilled engineering team. This synergy is crucial for achieving the precision required for complex components. The facility is meticulously organized to optimize workflow, from component fabrication and gear cutting to clean-room assembly and final testing. We employ advanced testing equipment to rigorously validate every unit, simulating real-world conditions to guarantee flawless operation. Furthermore, our facility houses a dedicated research and development wing, where our team of over five senior engineers collaborates with academic institutions. This focus on R&D ensures our transaxle production facility remains at the forefront of technological innovation, constantly pushing the boundaries of what is possible.

RUIPU MACHINERY: A Benchmark for Quality and Innovation

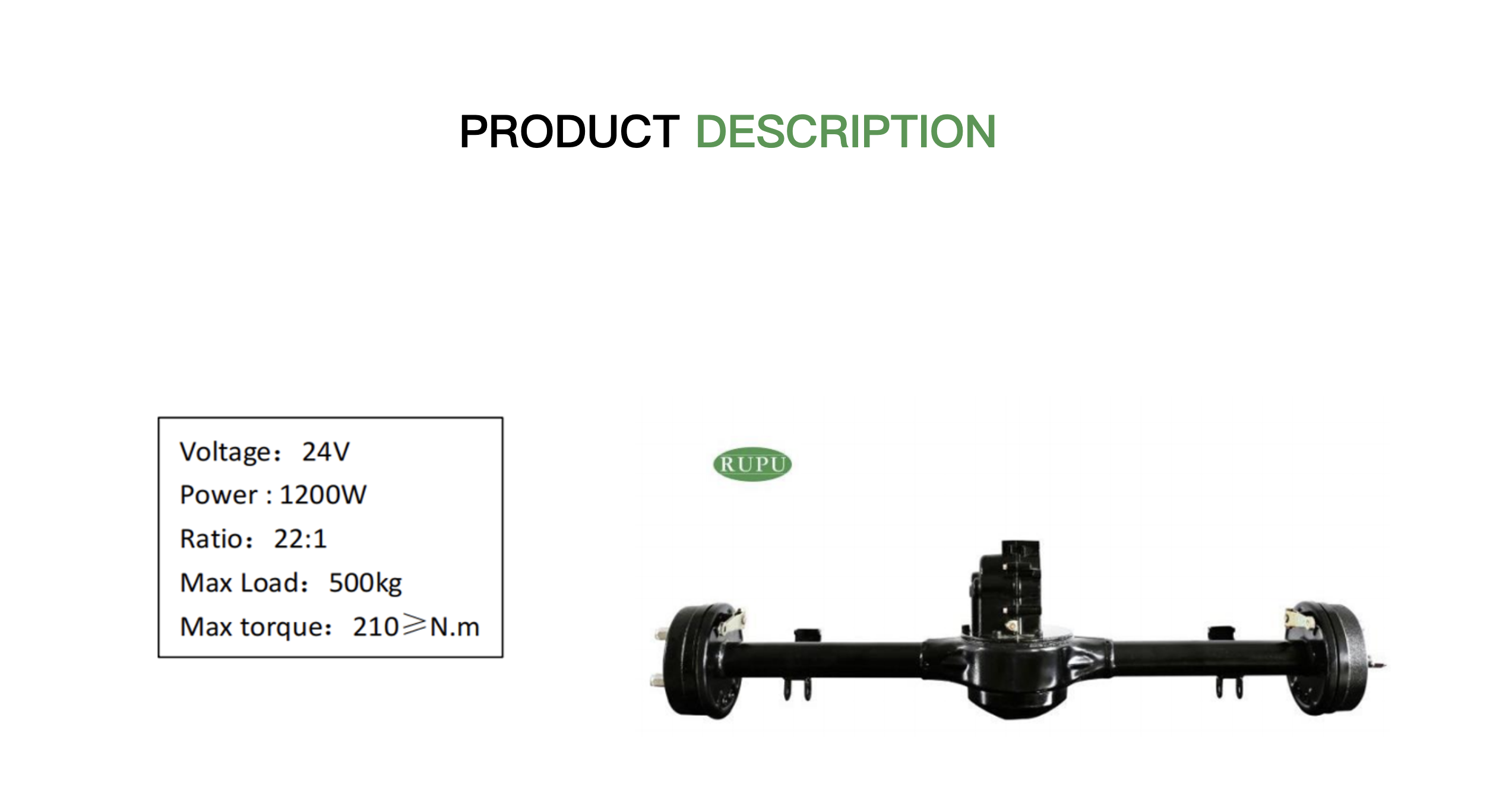

As a premier electric transaxle factory, RUIPU MACHINERY has established a reputation built on our core principles of honesty, pragmatism, and innovation. Our corporate philosophy centers on our responsibility to the customer, ensuring complete satisfaction and value creation. This is reflected in the tangible quality of our products. For instance, our cutting-edge Electric Drive Axle is a testament to our engineering prowess. Operating at 24V, it delivers a powerful 1200W output and a maximum torque of 210 N.m, making it ideal for a wide range of demanding applications. With a meticulously designed gear ratio of 22:1 and a maximum load capacity of 500 kg, it provides an optimal balance of speed, strength, and reliability. These specifications are not just numbers; they represent our commitment to delivering components that empower our clients' products to perform exceptionally in the real world.

The Future is Electric: Evolving Transaxle Technology

The journey of the electric vehicle transaxle is far from over. The industry is continuously evolving, with future developments focused on enhancing efficiency, reducing weight even further, and improving thermal management. Innovations such as multi-speed transaxles are being explored to optimize motor performance across a broader range of speeds, potentially boosting both acceleration and top-end efficiency. The use of new composite materials and advanced lubrication techniques also promises to increase durability and reduce mechanical friction. RUIPU MACHINERY is deeply invested in this future. Our dedication to continuous improvement and product diversification, supported by strong R&D, positions us to not only meet but also help define the next generation of electric drivetrain technology for the global market.

Partnering for a Greener Tomorrow

The transaxle is a fundamental pillar of the electric vehicle revolution, and its sophisticated design and manufacturing are critical for advancing clean energy transportation. The expertise and dedication found within a specialized facility are what transform raw materials into high-performance components that drive progress. With a global footprint spanning over 30 countries and a steadfast commitment to quality and service, RUIPU MACHINERY stands as a trusted partner in this journey. We welcome new and existing customers to connect with us, explore our innovative solutions, and build a future of mutual growth and success.