The Epicenter of Electric Vehicle Innovation

As the world accelerates its transition towards sustainable transportation, the demand for high-performance electric vehicles has never been greater. At the core of this revolution lies the intricate engineering of its components, and few are as critical as the transaxle. A premier electric transaxle factory is not merely an assembly line; it is a hub of innovation, precision, and quality, responsible for producing the very heart of an electric vehicle's drivetrain. RUIPU MACHINERY has established itself as a leader in this specialized field, operating a state-of-the-art facility dedicated to advancing the future of mobility through superior engineering and manufacturing excellence.

The Crucial Role of Electric Transaxle Manufacturing

An electric vehicle transaxle is a marvel of modern engineering, combining the functions of a transmission, differential, and drive axle into a single, integrated unit. This consolidation is vital for optimizing space, reducing weight, and enhancing the overall efficiency of an electric vehicle. The quality of electric transaxle manufacturing directly impacts a vehicle's performance, from its acceleration and handling to its energy consumption and reliability. A poorly manufactured transaxle can lead to decreased range, noisy operation, and premature failure. This is why manufacturers like RUIPU MACHINERY place an immense emphasis on every stage of the production process, from initial design and material selection to final assembly and rigorous testing. By controlling the entire manufacturing journey, a dedicated factory ensures that every component meets stringent standards for durability and performance, providing a seamless and powerful driving experience.

Inside a State-of-the-Art Transaxle Production Facility

Located in the bustling industrial city of Jinhua, Zhejiang, the RUIPU MACHINERY campus serves as a benchmark for a modern transaxle production facility. Spanning approximately 6,000 square meters, this factory is where innovation meets execution. Guided by a corporate spirit of Honesty, Civilization, Pragmatism, and Innovation, the facility is designed for efficiency and precision. A key advantage lies in our commitment to independently designing and producing all core components. This vertical integration allows for unparalleled quality control and the ability to rapidly innovate. The facility is equipped with advanced testing equipment to validate the performance of every unit, ensuring it can withstand the rigors of real-world applications. This meticulous approach to production solidifies our reputation as a leading electric transaxle factory, committed to delivering excellence from the ground up.

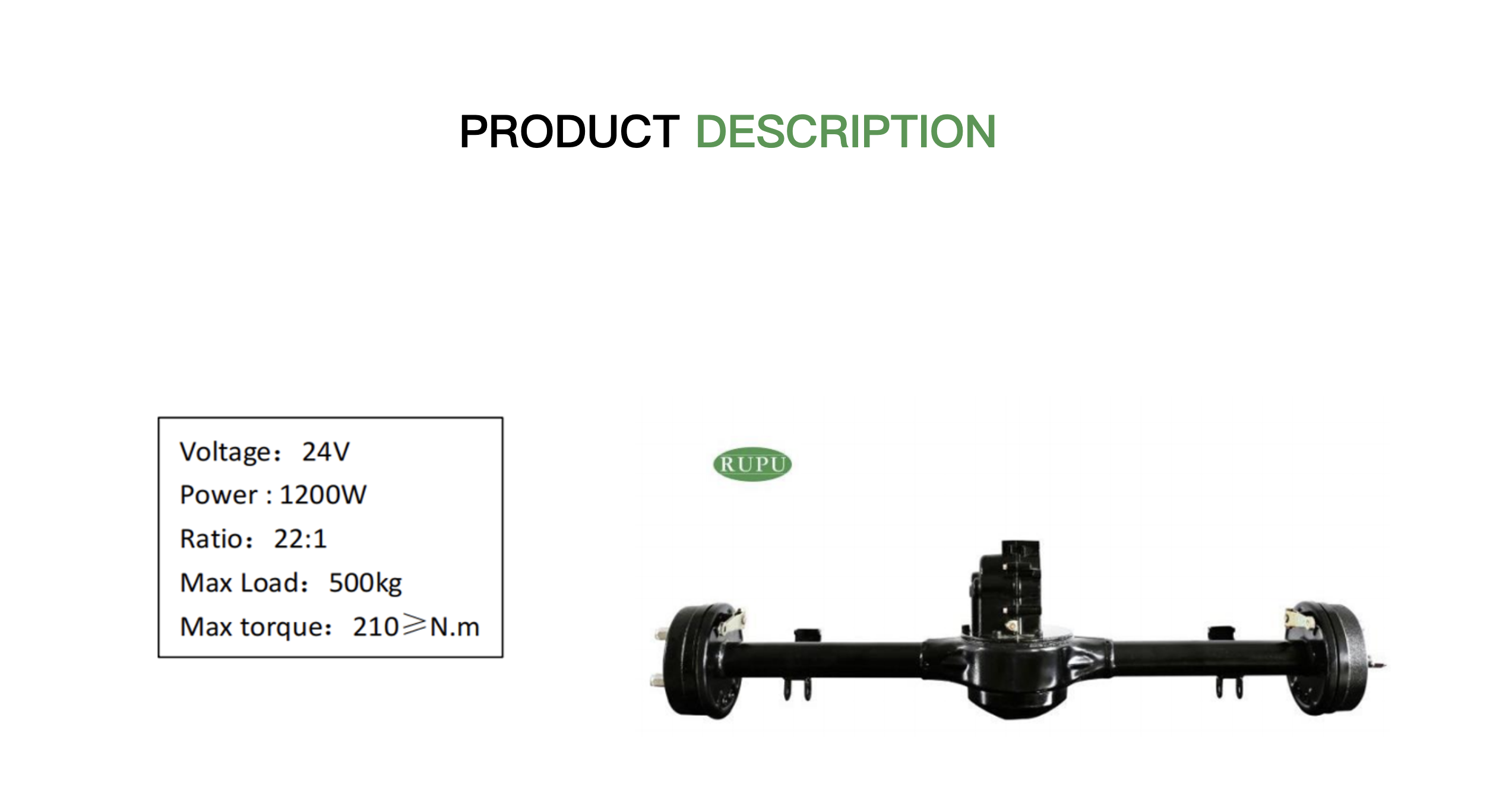

Engineering Excellence Embodied in RUPU Products

The output of our facility speaks volumes about our engineering capabilities. Take, for instance, the RUPU Electric Drive Axle. This powerful component operates on a 24V system and delivers a robust 1200 watts of power. It is engineered with a 22:1 gear ratio, which provides exceptional torque multiplication, essential for maneuverability and handling heavy loads. With a maximum load capacity of 500 kilograms and a torque rating exceeding 210 N.m, this electric vehicle transaxle is designed for a wide range of applications, from personal mobility vehicles to industrial transporters. Similarly, our 24 Volt Electric Differential offers the same powerful specifications, ensuring superior traction and stability. These products are not just components; they are a testament to what a dedicated electric transaxle production facility can achieve, blending power, efficiency, and unwavering reliability.

A Global Reach with a Focus on Customization

RUIPU MACHINERY’s commitment to quality has earned us a global reputation, with our products being exported to over 30 countries across Europe, North America, Australia, and Southeast Asia. This international footprint is supported by a team of over five senior engineers and strategic collaborations with universities, fostering continuous improvement and product diversification. We understand that the needs of the global market are diverse, which is why we specialize in developing customized products with special structures. Our clients value our ability to offer fast development cycles without compromising on reliable performance. This flexibility and customer-centric approach are cornerstones of our philosophy, where we see ourselves not just as a supplier but as a partner in our clients' success. Our expertise in electric transaxle manufacturing allows us to tailor solutions that precisely meet the unique demands of various vehicle designs and applications.

The RUIPU Advantage: A Legacy of Quality and Partnership

Our long-standing success, including being recognized as an excellent enterprise in Zhejiang Province in 2006, is built on a foundation of an uncompromising quality policy focused on Prevention, Control, Improvement, and Service. Every electric vehicle transaxle that leaves our factory is a product of this culture. We believe in taking responsibility for our customers, ensuring their satisfaction by delivering value that goes beyond the product itself. By integrating advanced technology, strict management practices, and attentive service, we provide a holistic partnership. As the electric vehicle market continues to evolve, RUIPU MACHINERY remains at the forefront, ready to meet new challenges and drive progress. We welcome new and existing customers to join us on this journey of mutual growth, powered by a shared vision for a more efficient and sustainable future of transportation.