Navigating the World of Advanced Electronics

In today's fast-paced technological landscape, the demand for smaller, more powerful, and feature-rich electronic devices has skyrocketed. At the heart of this innovation lies the intricate and sophisticated process of Complex PCB Assembly. This is not merely about placing components on a board; it is a highly technical discipline that combines precision engineering, advanced materials, and rigorous quality control to bring cutting-edge electronic concepts to life. As devices shrink and capabilities expand, the complexity of their internal architecture increases, making a deep understanding of this process more critical than ever for manufacturers and innovators alike.

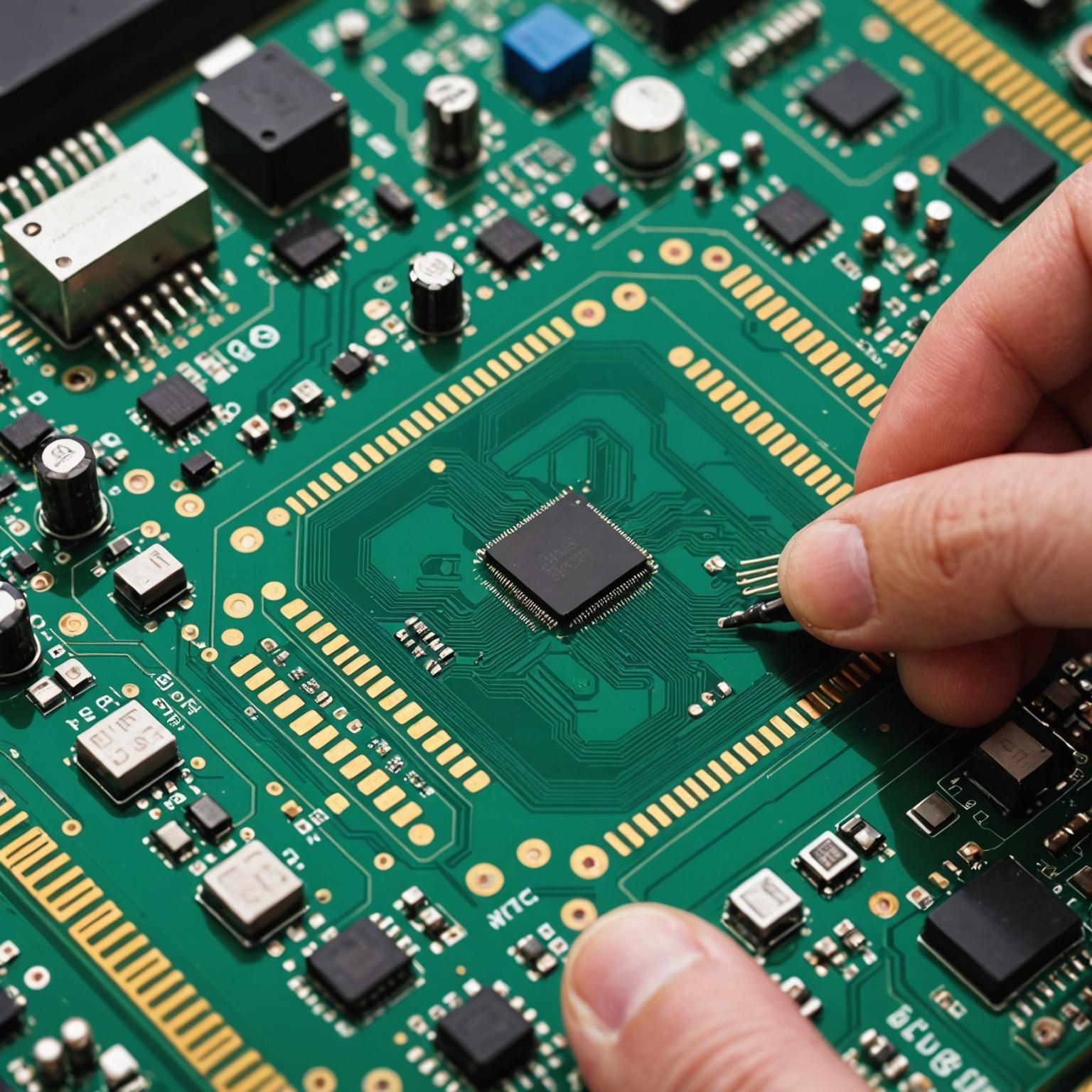

Defining Complexity in Modern Circuit Boards

What exactly elevates a standard board to a Complex PCB Assembly? The distinction lies in a combination of factors, including component density, technology integration, and manufacturing precision. Modern complex boards often feature a seamless integration of diverse technologies, such as Surface Mount Technology (SMT) and traditional through-hole methods, sometimes on the same board in a mixed-technology assembly. The challenge is amplified by the use of extremely small passive components, with sizes down to 0201 inches, and fine-pitch chips with a precision of up to 0.38mm. Furthermore, these assemblies incorporate advanced chip technologies like Ball Grid Array (BGA) with a pitch as fine as 0.2mm, Field-Programmable Gate Arrays (FPGA), Land Grid Arrays (LGA), and Quad-Flat No-leads (QFN) packages. These components are not only difficult to place accurately but also require specialized inspection methods, such as X-Ray, to verify solder joint integrity, making the entire Printed Circuit Board assembly a meticulous and demanding task.

The Intricate Process of PCB Manufacturing

Bringing a complex board from a digital design file to a physical, functional product is a multi-stage journey that demands expertise and advanced infrastructure. The PCB manufacturing process begins with a comprehensive set of design files, typically including Turnkey PCB Gerber RS-274X files, along with a Bill of Materials (BOM) and Pick-N-Place data. These files guide the automated machinery throughout production. Our process utilizes eight fully automated SMT lines for efficient and precise chip assembly, while a dedicated DIP workshop handles any necessary plug-in and post-welding tasks. We accommodate a wide range of board types, including Rigid, Metal Core, Flex, and Rigid-Flex PCBs, and offer various solder paste options like leaded, lead-free (RoHS compliant), and water-soluble pastes to meet diverse industry standards and environmental requirements. This comprehensive approach ensures that every project, from a 5-piece prototype to a 100,000-piece production run, is executed with the highest level of precision.

Unyielding Commitment to Quality and Testing

In the realm of complex electronics, quality is not an option; it is an absolute necessity. A single microscopic flaw can lead to intermittent failures or complete device malfunction. To prevent this, a robust quality control system is integrated into every stage of production. With 16 years of experience, we have established an independent quality inspection department that oversees everything from incoming material checks to final product assembly. Our quality assurance protocol includes multiple visual inspections by trained QC personnel. After the soldering stages, we employ Automatic Optical Inspection (AOI) to quickly and accurately detect potential defects. For components like BGAs where solder joints are hidden, we utilize advanced X-Ray inspection. Following assembly, In-Circuit Testing (ICT) and Flyneedle systems are used to identify soldering defects and component issues. Finally, voltage tests, chip programming, and comprehensive functional assessments are performed to guarantee that every board meets the highest standards of quality, reliability, and functionality, all in adherence with ISO9001 standards.

The Advantage of a Full-Service Manufacturing Partner

Successfully navigating the challenges of a Complex PCB Assembly requires more than just machinery; it requires a reliable and expert partner. We provide comprehensive services that extend far beyond simple assembly. Our flexible turnkey solutions cover everything from complete component sourcing from renowned, factory-direct suppliers to kitted or consigned setups based on your project's needs. For those starting from an idea, our ODM services are invaluable, offering hardware development, embedded systems design, industrial design, and expert PCB design backed by over a decade of experience. We pride ourselves on our core service advantages: sincere cooperation, the expertise of senior engineers who undergo regular training, remarkable efficiency with delivery times often within 48 hours, and strict data confidentiality. By managing the entire process, we empower our global clients to focus on innovation while we ensure their vision is manufactured to perfection.