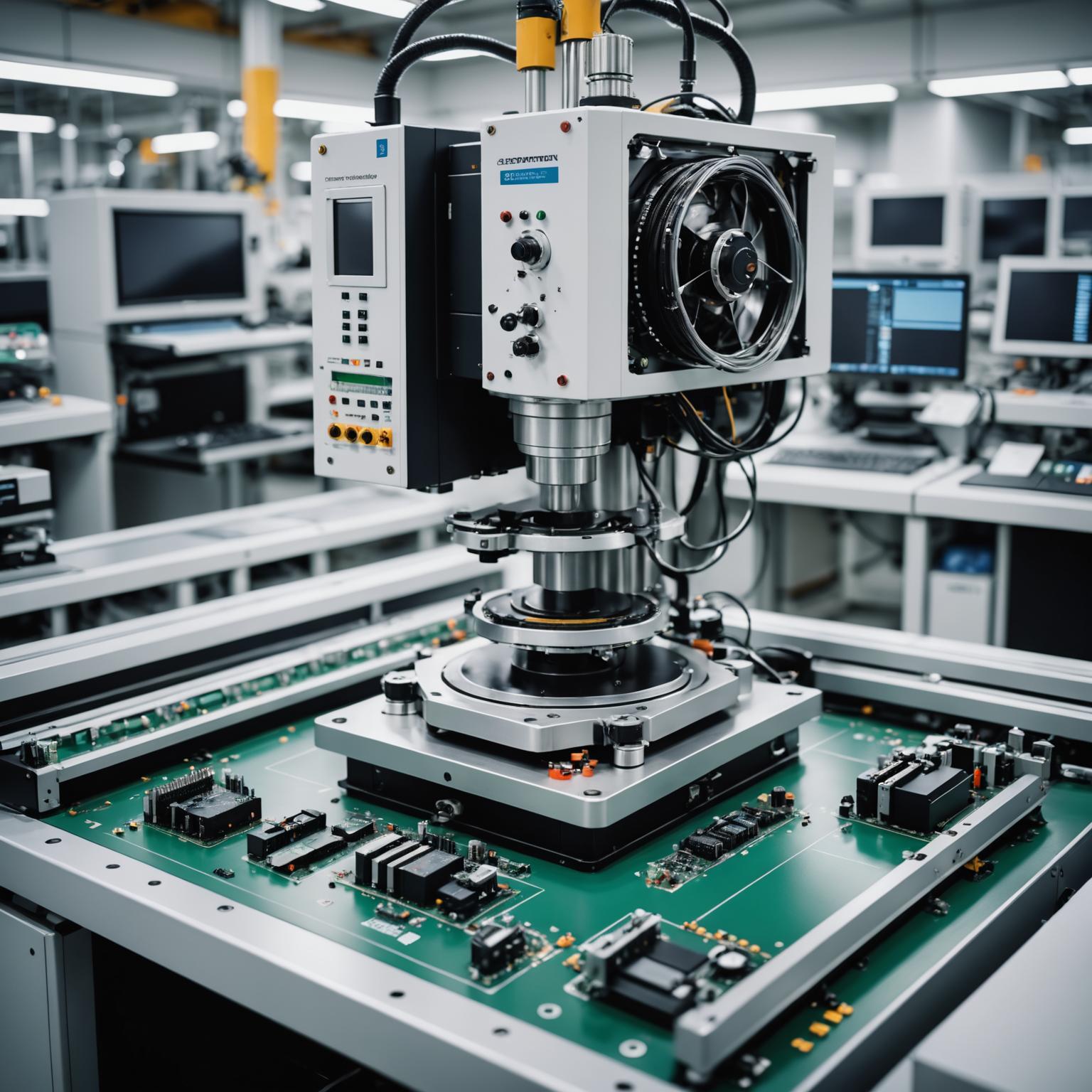

IC taping machine technology has revolutionized the electronics manufacturing industry by providing precise and efficient solutions for handling integrated circuits. This essential equipment, often referred to as an IC taping machine, ensures that components are securely taped for storage, transportation, and automated assembly lines. As a leading innovator in this field, I.C.T offers cutting-edge solutions that combine advanced engineering with reliable performance, helping businesses achieve higher productivity and accuracy in their operations.

The Evolution and Importance of IC Taping Machines

In the fast-paced world of electronics production, the need for reliable integrated circuit taping equipment has never been greater. An IC taping machine, such as those developed by I.C.T, automates the process of taping delicate integrated circuits onto reels, protecting them from damage and facilitating seamless integration into surface mount technology (SMT) lines. This technology not only minimizes handling errors but also speeds up production cycles, making it indispensable for manufacturers dealing with high volumes of components. I.C.T, with its global presence and decades of expertise, has been at the forefront of this evolution, establishing branches in key regions like Singapore, Germany, and the U.S. to better serve international clients. Their commitment to innovation is evident in machines that adapt to various component sizes and types, ensuring versatility for both small-scale and large-scale operations.

Key Features of I.C.T's IC Taping Machines

I.C.T's IC taping machines are designed with a focus on precision and user-friendly operation, featuring a sleek white body and a durable steel gray base that provides stability during high-speed processes. These machines incorporate advanced software interfaces that simplify configuration and reduce downtime, allowing operators to handle everything from initial setup to ongoing adjustments with ease. For instance, the I.C.T Intercontinental SMT Assembly Machine, which includes taping capabilities, offers high-speed placement and customizable feeders to accommodate different integrated circuit taping equipment needs. This means businesses can switch between component types without significant reconfiguration, enhancing flexibility in dynamic manufacturing environments. Moreover, I.C.T's emphasis on quality control is reflected in their rigorous internal auditing and proactive quality planning, ensuring that every taping machine for ICs meets international standards and delivers consistent results.

Benefits of Using Taping Machines for ICs in Modern Manufacturing

Utilizing a taping machine for ICs from I.C.T brings numerous advantages, including improved efficiency and reduced error rates in assembly processes. These machines help in securely packaging components, which is crucial for maintaining their integrity during transit and storage, ultimately leading to higher product quality and customer satisfaction. I.C.T's machines are optimized for both high-volume production and custom runs, making them suitable for a wide range of clients, from engineering offices to multinational corporations like Huawei and Foxconn. With over 5,000 equipment installations worldwide, I.C.T has demonstrated its ability to support global customers through comprehensive services, such as 24/7 online assistance and detailed traceability systems that provide inspection records for every order. This level of support underscores I.C.T's role as an all-round SMT solution provider, focusing on intelligent manufacturing and continuous R&D to address emerging challenges in the industry.

I.C.T's Global Reach and Commitment to Excellence

I.C.T, established in 2012, has grown into a trusted name in electronic manufacturing, with manufacturing plants in Shenzhen and Dongguan and partnerships in 56 countries. Their history of milestones, from entering the South Asian market in 2015 to surpassing $30 million in sales by 2023, highlights a dedication to expansion and technological advancement. The company's R&D team, comprising 15 experts, concentrates on developing intelligent solutions like the IC taping machine, which integrates seamlessly with other SMT equipment to streamline entire production lines. This holistic approach ensures that clients receive not just a product, but a complete ecosystem of support, including life cycle management and engineering assistance. By leveraging resources from joint ventures in Munich and Silicon Valley, I.C.T continues to push boundaries, offering machines that embody precision, reliability, and adaptability.

Future Trends and Innovations in IC Taping Technology

As the electronics sector evolves, the demand for advanced integrated circuit taping equipment is set to increase, driven by trends like miniaturization and smarter automation. I.C.T is preparing for this by investing in semiconductor units and expanding their overseas market share, which already accounts for over 60% of their business. Their IC taping machines are at the cutting edge, featuring adaptable technology that handles diverse component demands while maintaining high standards of quality. For businesses looking to stay competitive, adopting an IC taping machine from I.C.T means embracing a future-proof solution that enhances productivity and reduces operational costs. With a track record of serving over 1,600 customers and continuous improvements in manufacturing processes, I.C.T remains a partner of choice for those aiming to redefine standards in electronic assembly.