The Crucial Role of High-Quality Excavator Parts in Modern Construction

In the demanding world of construction, the reliability and efficiency of heavy machinery are paramount. Excavators, the workhorses of any significant project, depend heavily on the integrity and performance of their individual components. Therefore, understanding the importance of high-quality excavator parts is not just a matter of maintenance, but a cornerstone of operational success, safety, and profitability. From the powerful hydraulic systems that drive the massive arms to the robust undercarriage that navigates challenging terrains, every part plays a vital role in ensuring these complex machines perform optimally under pressure. Investing in superior components means investing in longevity, reduced downtime, and enhanced productivity on the job site.

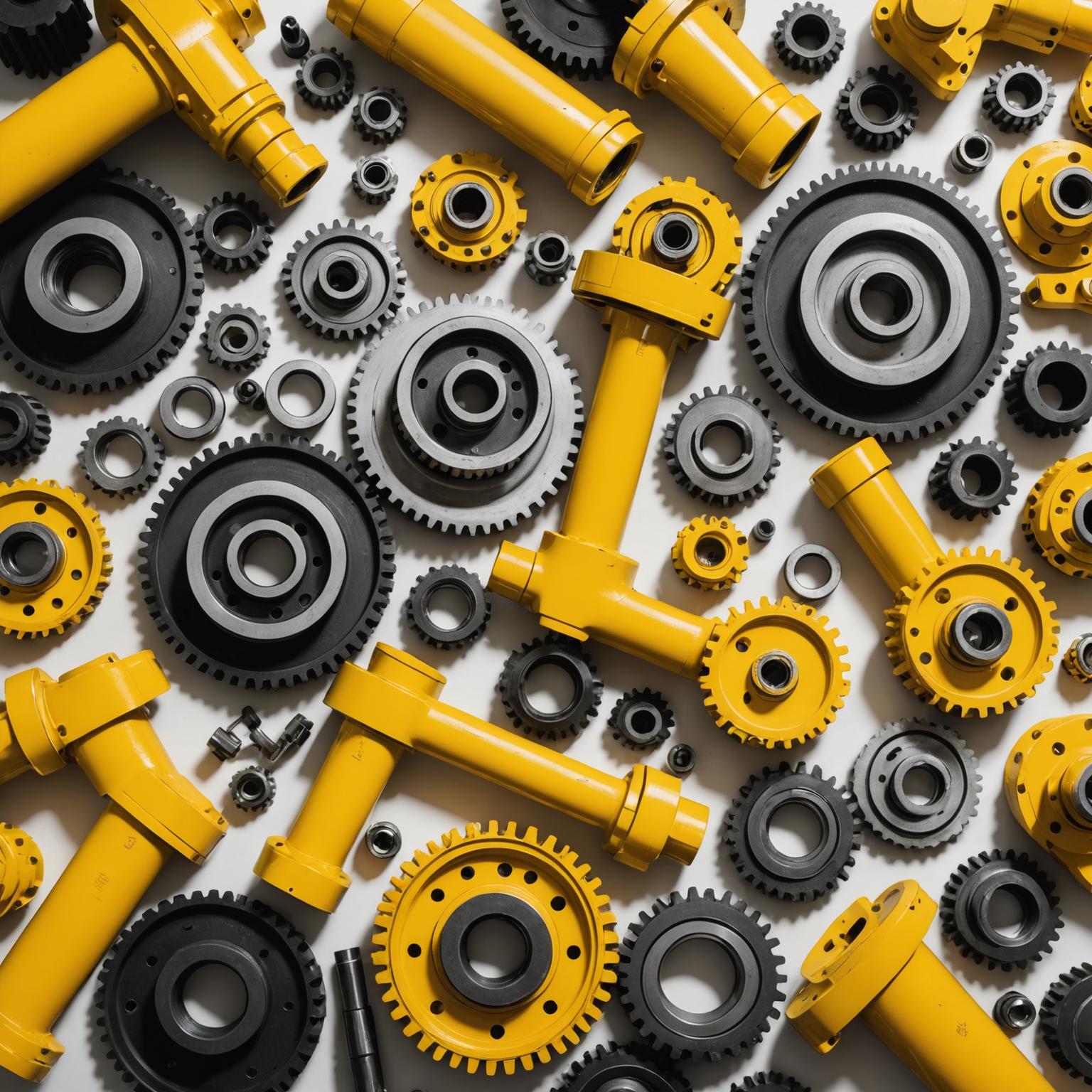

The Powerhouse Within: Advanced Hydraulic Motor Systems

At the heart of an excavator's immense power and precise movement lies its hydraulic system, with the hydraulic motor acting as a critical element. Modern hydraulic motors are marvels of engineering, designed to deliver seamless, high-performance precision for even the most complex tasks. These are not simple pumps; they are sophisticated units crafted from robust materials and developed through cutting-edge engineering processes. The benefit of such advanced design is twofold: maximum durability, ensuring the motor can withstand the rigorous demands of daily construction work, and minimal maintenance, which translates directly into less downtime and lower operational costs. A high-quality hydraulic motor ensures that the excavator’s digging, lifting, and maneuvering capabilities are consistently responsive and powerful, allowing operators to work with confidence and efficiency. The engineering focus on these motors also includes features that protect them from common worksite contaminants, further extending their operational life and sustaining peak performance over time. This dedication to quality in hydraulic systems is fundamental to the overall capability of any excavating machinery.

Precision in Motion: Transmission Gears and Planetary Gear Units

Effective power transmission is just as crucial as power generation in heavy machinery. This is where exceptional transmission gears and planetary gear units come into play. These components are meticulously engineered to enhance torque capacity, which is essential for an excavator to exert the necessary force for digging through tough materials or lifting heavy loads. Beyond sheer power, these advanced gear systems optimize every movement with deft accuracy. This precision is critical not only for efficient work but also for safety on a busy construction site. Furthermore, a significant advantage of modern gear units is their ability to reduce operational noise and vibration. This creates a more harmonious and less fatiguing working environment for the operator and reduces the environmental noise impact of the construction activities. These gears are designed for seamless integration with various types of heavy equipment, including excavators and bulldozers, highlighting their versatility and the sophisticated engineering that allows them to function reliably under diverse operational stresses and conditions. Their internal construction often features specially treated metals and precision machining to minimize wear and maximize power transfer efficiency.

Delivering Force Efficiently: The Role of Final Drive Units

The final drive units are often the unsung heroes of construction equipment, yet they are indispensable for an excavator's mobility and operational power. These compact but incredibly strong units are responsible for translating the hydraulic power generated by the motor and modulated by the transmission into the mechanical movement that propels the machine. Their primary function is to deliver superior traction and stability, which is vital when an excavator is operating on uneven, soft, or challenging terrains. A well-designed final drive ensures that the excavator can move safely and effectively, regardless of the ground conditions. The exceptional strength packed into their compact design is a testament to modern engineering, where space optimization does not come at the cost of performance. These units must withstand immense torque and shock loads, particularly when the excavator is traversing rough ground or making sharp turns. Therefore, their construction involves high-strength alloys and precision engineering to ensure they can deliver reliable performance in every circumstance, contributing significantly to the machine’s overall agility and work capacity. The integrity of the final drive is directly linked to the excavator's ability to position itself correctly and apply its digging force effectively, making it a key component for productivity.

Foundations of Mobility: Sprockets, Rollers, and Track Components

An excavator's ability to move around a job site is fundamental to its utility, and this mobility is provided by its undercarriage, specifically the sprockets, rollers, and track components. These vital parts are constantly under stress, supporting the machine's weight and enduring the friction and impact of movement across various surfaces. High-quality sprockets, rollers, and track chains are therefore designed with heightened wear resistance to maximize their lifespan and, consequently, the machine's uptime. Optimized uptime translates directly to increased productivity and reduced maintenance costs. The bright yellow finish often seen on these components is not merely for aesthetics; it often signifies a proprietary treatment designed to protect against environmental wear, such as rust and corrosion, further promising longevity and sustained excellence. Precision machining ensures that these components fit together perfectly, reducing unnecessary wear and tear and ensuring smooth, efficient movement. Regularly inspecting and maintaining these critical excavator parts is essential to prevent costly breakdowns and ensure the machine operates safely and efficiently throughout its working life. The synergistic operation of these undercarriage components dictates how well an excavator can navigate its environment, directly impacting project timelines and operational costs.

The Cumulative Impact of Superior Engineering in Excavator Parts

Choosing high-quality excavator parts is a decision that reverberates throughout the entire operational lifecycle of the machinery. Each component, from the robust hydraulic motors and precise transmission gears to the durable final drives and wear-resistant track components, embodies the pinnacle of modern engineering. This commitment to quality delivers unmatched reliability, ensuring that the equipment is always ready to perform when needed. Enhanced performance means tasks are completed more quickly and efficiently, while the overall efficiency contributes to lower fuel consumption and reduced environmental impact. When every part is designed for seamless integration and outstanding performance in the field, the result is a machine that operates at its peak potential, minimizing unexpected failures and extending its service life. This holistic approach to component quality is crucial for maximizing the return on investment in heavy construction equipment. Moreover, superior parts often come with better warranties and support, providing additional peace of mind and assurance of their long-term value.

Conclusion: Elevating Performance Through Quality Components

In conclusion, the performance, longevity, and safety of an excavator are directly tied to the quality of its constituent parts. Whether it's the hydraulic system delivering immense power, the gears ensuring precise movement, the final drives providing robust traction, or the undercarriage facilitating mobility, each element plays a crucial role. By prioritizing well-engineered, durable, and reliable excavator parts, construction businesses can significantly enhance their operational capabilities, reduce costly downtimes, and ensure their projects are completed efficiently and safely. Investing in the best available components is not an expense but a strategic decision that underpins the success and sustainability of any operation reliant on heavy machinery. This commitment to quality ultimately defines the effectiveness and profitability of construction endeavors worldwide.