What Defines a Complex Printed Circuit Board Assembly?

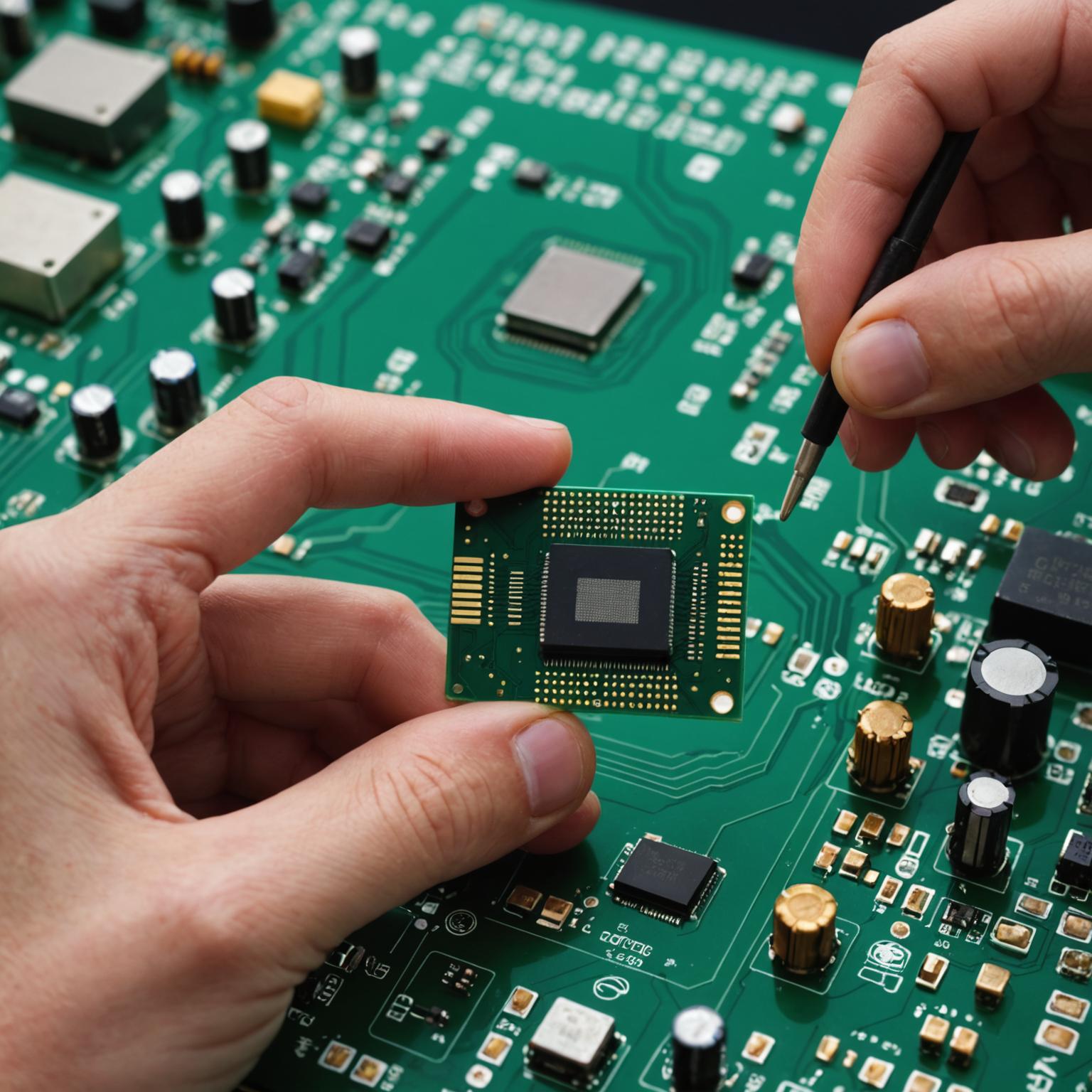

A complex board is characterized by its density, the sophistication of its components, and the advanced techniques required for its creation. This isn't your standard circuit board. We are talking about multi-layered boards that support a variety of assembly types, including Surface Mount Technology (SMT), Ball Grid Array (BGA), and traditional Through-hole Assembly. Often, these methods are combined in a mixed assembly to leverage the benefits of each. The components themselves are a marvel of miniaturization. Imagine passive components as small as the 0201-inch standard, or fine-pitch chips with a precision down to 0.38mm. BGAs, with their connections hidden underneath the chip, can have pitches as fine as 0.2mm, requiring specialized inspection. The Printed Circuit Board assembly may also feature a variety of advanced chips like FPGAs, LGAs, and QFNs, all packed onto diverse board types ranging from rigid and metal core to flexible and rigid-flex designs, tailored for specific and demanding applications.

The Intricate Process of PCB Manufacturing

The journey of a complex board from concept to reality is a meticulously managed process. It begins with a detailed set of design files, such as the Gerber RS-274X for the board layout and a comprehensive Bill of Materials (BOM) that lists every single component. A Pick-N-Place file provides the exact XY coordinates for automated component placement, which is crucial for accuracy. The actual PCB manufacturing process then begins. In a state-of-the-art facility, automated SMT lines handle the precise placement of surface-mounted components, while a dedicated DIP workshop manages plug-in and post-welding tasks for through-hole components. A critical part of this process is component sourcing. A full turnkey solution, where the manufacturer sources all parts, offers a seamless and efficient experience for the client. Alternatively, partial turnkey or kitted options provide flexibility, allowing clients to supply some or all of their own components. This entire workflow is designed to handle everything from small prototype runs of just a few pieces to mass production scaling into the hundreds of thousands, ensuring consistency and quality at every volume.

Ensuring Uncompromising Quality in Every Board

With complexity comes a greater risk of error, making quality control the most critical stage in the production of a Complex PCB Assembly. A multi-faceted testing strategy is essential to guarantee reliability. After the printing and soldering stages, an Automatic Optical Inspection (AOI) system scans the board to quickly identify any visual defects. For components like BGAs where the solder joints are not visible, X-Ray inspection is employed to look beneath the chip and verify every connection is perfect. Following assembly, an In-Circuit Test (ICT) or Flying Probe test checks for soldering defects, opens, shorts, and incorrect component values. Finally, voltage tests, chip programming, and full functional tests are conducted to ensure the board operates exactly as designed. This commitment to quality is upheld by an independent quality inspection department that monitors every single stage, from incoming raw materials to the final packaged product, often adhering to strict international standards like ISO9001.

The Advantages of Partnering with an Expert Manufacturer

Navigating the world of advanced electronics requires a partner with proven expertise, robust processes, and a commitment to client success. A seasoned expert in Printed Circuit Board assembly offers more than just production; they provide a reliable partnership. This includes a team of senior engineers who maintain high design standards and undergo regular training to stay at the forefront of technology. Efficiency is another key advantage. With optimized processes, a manufacturer can offer incredibly fast assembly lead times, sometimes as quick as 8 to 72 hours once all parts are ready, which is a significant competitive edge. Furthermore, for businesses developing proprietary technology, data security is paramount. A professional manufacturing partner will have secure data management protocols to ensure all design files and intellectual property remain strictly confidential. From initial design support and hardware development to scalable production and final testing, a comprehensive service provider becomes an extension of your own team, dedicated to bringing your technological vision to life with precision and reliability.